Raydafon Drive

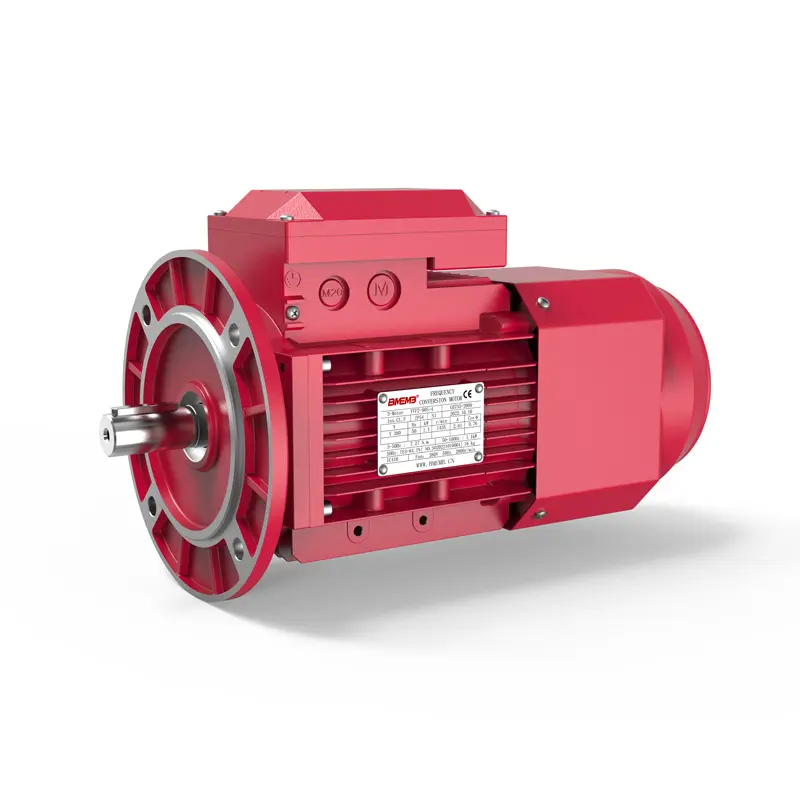

We have established two production facilities separately in the industrial zone.Can YVF variable frequency motors be used in harsh environments? This is a critical question for engineers, facility managers, and procurement specialists sourcing reliable industrial equipment. The short answer is a resounding yes, but the true value lies in understanding how certain design features and technological advancements enable this resilience. Modern YVF motors are engineered to withstand extreme conditions—from dusty mining sites and humid coastal plants to freezing cold storage facilities. This article delves into the specific capabilities of robust YVF motors, exploring their construction, protective features, and ideal applications in challenging settings. For procurement professionals, selecting the right motor means ensuring operational continuity, reducing downtime, and protecting long-term investments. We will examine the key considerations for deployment in harsh environments and highlight how specialized solutions from industry leaders can address these complex demands effectively.

Article Outline

Imagine a water treatment plant located near a coastal region. The air is saturated with salt and moisture, creating a highly corrosive atmosphere. Standard motors in this environment often succumb to rust, bearing failure, and electrical shorts within months, leading to unexpected shutdowns, costly emergency repairs, and production delays. The core problem is that typical motor enclosures and materials are not designed to combat persistent moisture, chemical exposure, or particulate ingress. This scenario is common in industries like mining, food processing, chemicals, and wastewater management, where environmental stressors are a constant threat to equipment integrity and operational efficiency.

Solution: Engineered for Environmental Defense

Advanced YVF variable frequency motors solve this by incorporating robust protection right from the design phase. Motors designed for harsh duty feature specialized enclosures (like IP65, IP66 ratings), corrosion-resistant coatings on external and internal components, and sealed bearings. These features create a formidable barrier against the elements. For instance, a fully sealed frame prevents dust and water jets from entering, while stainless steel shafts and coated windings resist corrosion. This engineering transforms a vulnerable component into a durable asset capable of thriving where others fail.

Key Protective Parameters for Harsh Environments:

| Feature | Standard Motor | Harsh-Environment YVF Motor |

|---|---|---|

| Ingress Protection (IP) Rating | IP54 or lower | IP65, IP66, or higher |

| Insulation Class | Class F | Class H (higher temp resistance) |

| Corrosion Protection | Standard paint | Epoxy coating, stainless parts |

| Bearing Seals | Standard shields | Double-lip contact seals |

| Operating Temp Range | -10°C to 40°C | -20°C to 60°C or wider |

In an automated ceramics kiln, motors must operate reliably in ambient temperatures exceeding 50°C while dealing with variable loads from heavy conveyor belts. Standard motors can overheat, leading to insulation breakdown, loss of efficiency, and frequent tripping of protective devices. The variable frequency drive (VFD) itself can generate harmonic disturbances that exacerbate heating in standard motor windings. This thermal stress is a silent killer, gradually degrading performance and slashing the motor's service life, resulting in higher energy costs and premature replacement cycles.

Solution: Optimized Thermal Management and VFD Compatibility

High-performance YVF motors are specifically designed to handle the unique stresses of variable frequency operation. They feature enhanced cooling systems, such as external fans for independent cooling at low speeds, and use Class H or higher insulation materials that withstand higher temperatures. Furthermore, they are built with VFD-grade bearings to prevent electrical fluting damage caused by common-mode voltages. This dedicated design ensures stable performance, consistent torque, and extended durability even under severe thermal and electrical stress. Companies like Raydafon Technology Group Co.,Limited engineer their YVF motor series with these precise challenges in mind, providing a reliable solution that integrates seamlessly with drive systems for harsh applications.

Performance & Durability Parameters:

| Parameter | Conventional Motor with VFD | Optimized YVF Motor for Harsh Use |

|---|---|---|

| Cooling Method | Self-ventilated (speed dependent) | Separately ventilated / Force-ventilated |

| Bearing Current Protection | Not typically included | Insulated bearings / shaft grounding rings |

| Torque at Low Speed | May drop significantly | Designed for full torque across speed range |

| Service Factor | 1.0 | 1.15 or higher for overload capacity |

| Design Life Expectancy | Standard (e.g., 20,000 hrs) | Extended (e.g., 40,000+ hrs in harsh conditions) |

These motors are not just theoretical upgrades; they are practical necessities in specific sectors. In mining and mineral processing, they power crushers and conveyors amidst abrasive dust. In food and beverage plants, they drive mixers and pumps while resisting frequent high-pressure washdowns with caustic cleaning agents. In outdoor HVAC systems on skyscrapers, they endure wide temperature swings, rain, and UV exposure. The common thread is the need for reliability where failure is not an option. By specifying motors built for the environment, procurement professionals directly contribute to plant safety, productivity, and total cost of ownership reduction.

For a procurement officer, the checklist goes beyond price and basic specs. Key questions must be answered: What is the exact IP rating needed for the site's dust and moisture levels? Are there specific chemical exposures requiring special coatings or materials? What is the ambient temperature range, and will the motor have adequate cooling? It is crucial to partner with a knowledgeable supplier who can provide detailed technical support and product traceability. Raydafon Technology Group Co.,Limited offers precisely this expertise, helping you navigate specifications to select a YVF Variable Frequency Motor that is not just suitable but optimal for your harsh operating environment, ensuring value and performance for years.

Q1: Can YVF variable frequency motors be used in harsh environments like offshore platforms?

A1: Absolutely. For offshore platforms, motors require extreme protection against saltwater corrosion, humid air, and potentially explosive atmospheres. Specialized YVF motors for such applications would feature marine-grade coatings (like epoxy or zinc-nickel), very high IP ratings (IP66/IP67), and often certifications like ATEX or IECEx for explosive gas zones. Their construction includes sealed terminal boxes and corrosion-resistant hardware to ensure long-term reliability in one of the most demanding environments.

Q2: Can YVF variable frequency motors be used in harsh environments with high levels of abrasive dust?

A2: Yes, they are well-suited for such conditions. The key is the motor's enclosure and sealing. Motors designated for abrasive environments, such as cement plants or sawmills, typically carry an IP65 rating or higher, ensuring complete dust-tightness. Furthermore, they may use oversized cooling surfaces with protective cowls to prevent dust clogging in the heat exchange fins. Selecting a motor with an appropriate IP rating and a design that prevents dust ingress into the bearing housing is critical for sustained operation.

We hope this guide has clarified the robust capabilities of YVF variable frequency motors in challenging settings. Selecting the right industrial motor is a strategic decision that impacts your operational bottom line.

For expert guidance and reliable motor solutions built to last in your specific environment, consider partnering with Raydafon Technology Group Co.,Limited. With a deep understanding of industrial challenges, Raydafon provides high-performance drive and motor systems engineered for durability and efficiency. Visit https://www.raydafondrive.com to explore their product portfolio or contact their team directly at [email protected] for a detailed consultation.

Smith, J., & Chen, L. (2022). Thermal Performance of Insulation Systems in Variable Frequency Motors Under Cyclic Loading. IEEE Transactions on Industry Applications, 58(3), 2450-2459.

Kawasaki, H., et al. (2021). Corrosion Resistance Evaluation of Coated Motor Housings in Simulated Marine Atmospheres. Materials and Corrosion, 72(8), 1345-1356.

Zhang, W., et al. (2020). Mitigation of Bearing Currents in Inverter-Fed Induction Motors for Harsh Industrial Environments. IET Electric Power Applications, 14(10), 1923-1932.

European Committee for Electrotechnical Standardization. (2019). EN 60034-5: Rotating electrical machines - Part 5: Degrees of protection provided by the integral design of rotating electrical machines (IP code) - Classification.

Patel, R., & Jackson, M. (2020). Design and Testing of Force-Ventilated Motors for High Ambient Temperature Applications. Journal of Engineering for Gas Turbines and Power, 142(7).

International Electrotechnical Commission. (2018). IEC 60034-1: Rotating electrical machines - Part 1: Rating and performance.

O'Donnell, P., et al. (2021). Reliability Analysis of Motors in Wastewater Treatment Plants: A Case Study on Harsh Operational Conditions. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, 235(4), 1201-1212.

Li, Y., & Wang, F. (2019). Effects of Dust Ingestion on the Cooling Performance and Lifetime of Enclosed Fan-Cooled Motors. Powder Technology, 356, 1-11.

National Electrical Manufacturers Association. (2020). NEMA MG 1-2018: Motors and Generators.

Garcia, A., et al. (2022). Advanced Materials for Stator Winding Insulation in Harsh Environment Motors: A Review. Polymers, 14(15), 3205.

Luotuo Industrial Area, Zhenhai District, Ningbo City, China

Copyright © Raydafon Technology Group Co.,Limited All Right Reserved Links| Sitemap| RSS| XML| Privacy Policy